|

ABOUT THE GROUP |

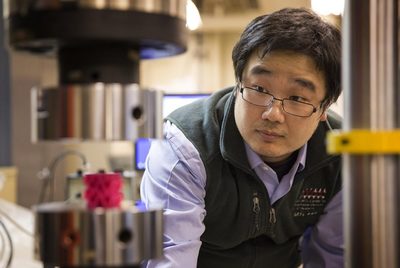

Laboratory for Multiscale Material Modeling

|

The group’s long-term goals are to discover fundamental principles that govern the multiscale mechanics of solid and lightweight composite materials and closely integrate research into education and outreach to advance education in Science, Technology, Engineering, and Math. These goals are enabled by studying a few typical natural systems and revealing their structure-mechanics relationship, including: 1. Mycelium 2. Natural composites 3. Carbon-based cellular materials.

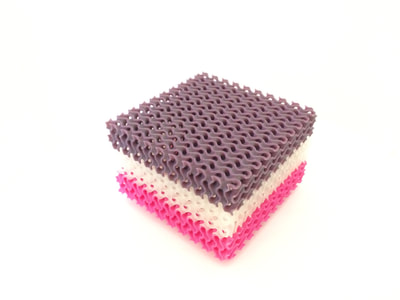

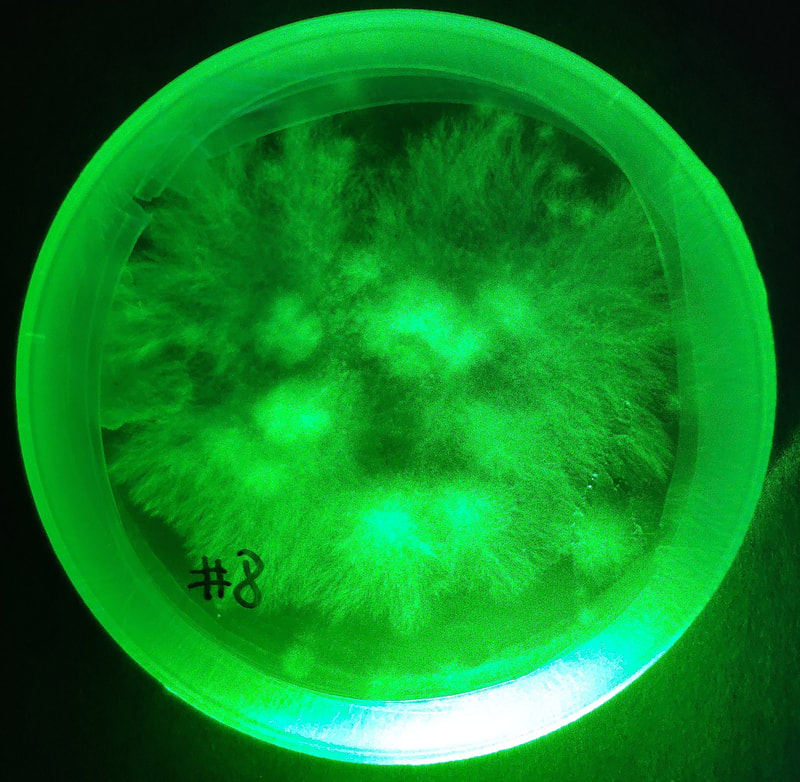

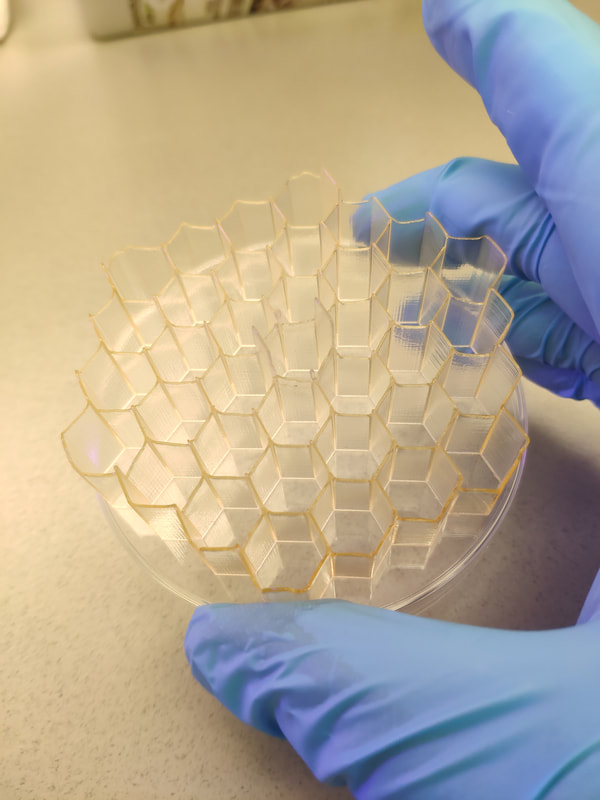

Mycelium fibers are massively produced underground during mushroom growth and play an essential role in stabilizing soil and facilitating plant growth, enabling a suitable living environment. Mycelium fibers naturally form entanglement and bonds to integrate organic wastes and generate strong and lightweight network without adding synthetic glues or energy input. A fundamental multiscale understanding of mycelium composites' mechanics will help develop strategies and green composite materials to preserve land by improving soil mechanics, reducing organic wastes, and providing lightweight materials to infrastructure with mechanical advantages. Natural composites including mineralized composite materials (e.g., nacre, enamel, bamboo skin, sandworm jaw, mussel adhesion) provide solutions of integrating materials of very different mechanics (i.e., from ultra-soft to extremely hard) from the atomistic to the continuum scales for advanced material functions with efficiency in material and energy usage. Multiscale modeling is used to model the physics of different bonds including hydrogen, ionic and covalent bonds with fidelity. Knowledge learned from these systems may be used for a more efficient design of the interface between different materials, which could be important to improve the design in securing engineering parts in multiple fields from tendon surgery to the marine industry. The development of synthesis of carbon materials with pre-designed nanoarchitectures demonstrates the feasibility of realizing the covalently bonded carbon networks through chemical vapor deposition or advanced manufacturing of polymer networks (e.g., 3D printing, biosynthesis, etc.) and pyrolysis of the polymer network. The mechanics and scaling of these highly integrated architectures are very different from the networks self-assembled by weak interactions. It is necessary to develop predictive tools that enable to predict how different pyrolysis conditions lead to different mechanical properties of the constituting material at the microscopic scale and how different lattice structure yield different mechanics and scaling law at the macro scale and optimize the process and structure thereafter. |